Future of Bridges | Florida bridge collapse has

some hard lessons

BY MARK HANSFORD - 16 DEC, 2019

A litany of failures ultimately combined to

cause the collapse of the Florida International

University (FIU) Bridge onto a live highway,

according to the official investigation into the

accident.

Key companies and organizations involved in the

project were criticized in the final report into

the collapse published by the US National

Transportation Safety Board (NTSB) (New Civil

Engineer last month).

Calculation errors

It concludes that design calculation errors made

by Figg Bridge Engineers were ultimately to

blame.

But failures by the independent design checker,

client, contractor and on-site construction

supervisor also contributed to the disaster,

which killed six people (see box). All had the

chance to act when serious cracks appeared in

the structure in the two days before the

collapse, but none did.

So this month we ask: what can we learn from

this failure?

Tony Gee & Partners group director of structures

Akram Malik, has spent 20 years examining why

structures collapse – particularly as a tool for

learning. So who better for New Civil Engineer

to ask to review the FIU collapse?

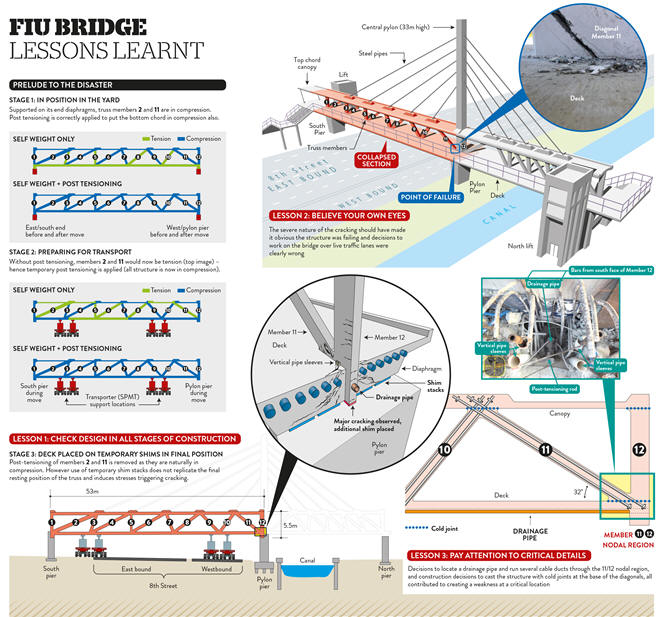

The structure included a 53m long prefabricated

main span made up of a 5.5m deep concrete truss

of 12 diagonal members. The truss supported the

10m wide deck and a 5m wide canopy running along

its length. The main span connected to a side

span around a central pier onto which a 33m tall

central pylon was to be built. This was an

architectural feature with 10 diagonal steel

“pipes” hanging from it to provide additional

stiffness but no other structural function.

It was at the connection between the two spans

and the pier – known as 11/12 nodal region –

that the failure occurred.

The client for the bridge was Florida

International University. It hired MCM as design

and build contractor, and MCM hired Figg as

designer and to serve as engineer of record.

Figg then contracted consultant Louis Berger to

conduct the required independent peer review of

the structural design. FIU also hired Bolton

Perez as construction engineering and inspection

contractor to monitor and inspect the bridge as

it was constructed. Florida Department for

Transportation (FDOT) is the highway authority

responsible for SW 8th Street, the road onto

which the bridge collapsed.

Independent checker role

Malik believes there are key lessons to be

learned, the clearest concerning the role of the

independent checker.

“Independent checking when required should

include every critical stage of construction,”

he states.

“Here, we’ve got Louis Berger who was engaged by

Figg, and Figg only asked it to look at the

final design, not the interim construction

stages – and both failed to see that the

intermediate construction stages were actually

critical in the failure”.

At face value the independent peer review

process was good. The structure was deemed a

“category 2” structure, for which the required

checks are similar to the UK Highways England’s

“category 3” process. “So a proper check was

required,” notes Malik, although he adds that

the exact requirements were unclear from

documents he has seen.

Computer image of Florida International

University Bridge

What is clear, from the NTSB’s report, is that

Louis Berger dropped its price from $110,000

(£84,000) under pressure from Figg whose budget

for this work was £46,500. Emails obtained by

investigators show Louis Berger warning Figg

that in seeking lower bids, FIU should be aware

that “a lesser fee may be associated with less

effort/value”.

More emails show that on contract award the

original scope of work remained unchanged, but

that Louis Berger had reduced the time it was

prepared to spend on checks from 10 weeks to

seven.

Peer reviewer requirements not met

Investigators also found that Louis Berger

failed to meet FDOT requirements for a peer

reviewer to employ at least three registered

professional engineers, each with a minimum of

five years’ experience in designing complex

concrete bridges.

Louis Berger performed the independent peer

review of Figg’s design using Adina, a finite

element analysis software program, in accordance

with FDOT standards. Post-collapse, Louis Berger

confirmed to NTSB investigators that it analyzed

the design as one structure in its completed

state. It only analyzed the design for the

completed structure and not for its various

construction phases.

“Doing construction sequence staging analysis

was not part of our scope. Doing such an

analysis requires much more time than what we

agreed about [with Figg],” it told

investigators.

The significance of failing to consider the

structure in its construction configurations

became clear when investigators began examining

the construction sequence, explains Malik.

The entire 53m long main span structure was

built off-site and then moved into its final

position on mobile transporters where it was set

on temporary shims.

Changing support system

Ahead of the move, the two end diagonals of the

truss were tensioned to ensure they remained in

compression while in transit (see diagram).

In the casting yard there was full contact

support across the deck and its two ends, yet

while resting on the pier the shims were placed

either side of the central truss – meaning there

was no direct support under the truss location.

This induced unexpected stresses and strains in

the structure which were exacerbated when the

end diagonal truss member was de-stressed after

it was positioned. This triggered the

significant cracking which should have given

warning that collapse was imminent. Such a

critical construction stage should have been

modelled by the checking engineer, Malik

concludes.

A second key lesson, says Malik, is the

old-adage of the devil being in the detail.

Investigators have overwhelmingly concluded that

the trigger for the collapse was punching shear

failure at the node where the end vertical and

diagonal truss members met. The NTSB has been

unequivocal in stating that Figg’s load and

capacity calculation errors at this key node

probably led to the failure. Post-collapse

calculations showed that the load demand on the

node was twice that designed.

Error went unnoticed

Louis Berger, as design checker, should have

noticed this error.

In a post-collapse interview, the Louis Berger

engineer who conducted the peer review told the

NTSB that the agreed budget did not stretch to

this level of analysis.

“In the beginning, I suggested to do this kind

of analysis, to analyze the connections,” he

said. “I’m talking about the nodes, or the

joints to analyze the connections. However, the

budget and time to do this actually was not

agreed upon with the designer.”

“Clearly in this case no-one looked carefully

enough at what was a really critical location,”

says Malik.

Malik points to a host of obvious deficiencies,

including decisions to locate a drainage pipe

and run several cable ducts through the critical

11/12 nodal region and construction decisions to

cast the structure with cold joints at the base

of the diagonals. He also questions the quality

of preparation of the construction joints.

“You have to look at the construction assurance

– was it wise to have the cold joint in such a

critical zone, that’s one question, and was it

prepared correctly? And we’ve got [on-site

supervisor] Bolton Perez Associates – did it do

its job? These are all questions that are a

little bit up in the air,” he says.

Retensioning to close cracks

One of the most alarming aspect of this collapse

was that the only action taken to stabilise the

structure – even when cracks up to 100mm deep

starting appearing – was to re-tension cables in

the end diagonal in the hope that this would

close the cracks.

Again, here there are clear lessons to learn,

says Malik. “In this case it appears that Figg

didn’t recognize that the structure was on its

way to collapsing.”

“It carried out calculations and those

calculations seemed to show that it was working

fine and that the cracks should not be

occurring.

“So it freely admitted that it didn’t understand

why the cracks were occurring, but on that basis

still decided to restress the bars to try and

arrest what was happening – even though it

didn’t understand it. This was poor decision

making,” he says.

Malik suggests that engineers should be educated

in the pre-collapse behaviour of structures. “Do

we need to include in our design processes an

additional question: ‘What are the ways in which

this structure could fail?’”

Malik’s final observation concerns the safety

management of the remedial action being taken –

restressing of the diagonal member above live

traffic.

“So… [site workers] were restressing the bars in

a critical member on a non-redundant structure

and were doing so over live traffic. Obviously

it was not a good decision in hindsight but even

in foresight it was not a good decision,” he

asserts.

And here he believes all parties should have

stepped in. But why didn’t they? “Are we

becoming too specialized?” he asks. Builders

build, designers design, supervisors supervise.

Is this preventing them from “exercising their

own independent professional judgement”?

Figg and MCM, Louis Berger and Bolton Perez have

been contacted for comment.

Investigators View: Bruce Landsberg - NTSB vice

chairman

A bridge-building disaster should be

incomprehensible in today’s technical world. We

have been building bridges in the United State

for over 200 years, and long before that in

other parts of the world. The science should be

well sorted out by now – and for the most part,

it is.

The investigation clearly highlighted basic

design flaws and a complete lack of oversight by

every single party that had responsibility to

either identify the design errors or stop work

and call for a safety stand-down, once it was

clear that there was a massive internal failure.

The “what” is very clear but the “why” is more

elusive. Despite the public’s anger, distress,

and disappointment, none of the responsible

organizations had any intent for this tragic

event to occur or to cause any injury or loss of

life. Sadly, good intentions do not suffice for

competence and diligence.

Engineering schools will use this as a landmark

case study for years – and they should.

The Engineer of Record employed by Figg was

experienced, but his calculations were

erroneous. Reflection on this event should go

far beyond merely a technical review. The checks

and balances that were required by the Florida

Department of Transportation (FDOT) and American

Association of State Highway and Transportation

Officials guidance and incumbent upon Louis

Berger, the peer-reviewing organization, were

completely lacking.

Louis Berger lowered its bid to review the

project by 43% in order to get the business, but

also reduced the scope of the review. The reason

given was there wasn’t enough money in the

project to cover its efforts. That’s both

disingenuous and unconscionable. It also was in

violation of FDOT’s requirement that there be an

independent second set of eyes to review

everything – not just what was economically

convenient.

It is likewise incomprehensible and unethical

that Louis Berger would even bid on a job for

which it lacked the requisite qualifications

(see main feature). That FDOT, which was

supposed to review the plans, did not know, or

think to ask, about its qualifications is more

than just an oversight. It’s just plain sloppy.

Ditto for Figg.

FDOT claimed a technical error on the FDOT

website and then, after the collapse, fabricated

a disclaimer that it is not responsible for the

data that it posts. That’s unacceptable in my

view – either ensure the information is accurate

or don’t post it.

The bridge was not properly designed, and there

was no qualified oversight on that design. When

the inevitable began to happen – a creeping,

catastrophic material failure, nobody did

anything, despite what NTSB chairman [Robert]

Sumwalt accurately described as the “bridge

screaming at everyone that it was failing.” Why?

Once the cracking became evident, not one of the

organizations involved was willing to take the

essential and unpopular step to call a halt and

close the road.

This is similar to the circumstances of the

space shuttle Challenger disaster where the

decision was made to launch in extremely cold

weather. The engineers recommended against it

because the O-Rings that were critical to fuel

system integrity would be operating outside

their design parameters. Rationalization,

optimism and schedule pressure contributed to

what has been described in management training

circles as “Group Think.” Strong and confident

personalities persuade everyone that everything

will be OK. Despite misgivings and technical

expertise that advise against such action, the

team moves forward as a group.

It appears that the same mindset was in play

here, in every organization: Figg, Louis Berger,

MCM (the construction company), Bolton Perez

(the engineering firm overseeing the bridge

construction), FDOT, and finally, Florida

International University. It also appears that

every organization absolved themselves of

responsibility by rationalizing that if the

Engineer of Record says it’s OK, it must be OK,

and if anything bad happens – it’s on him. That

is not the intent of peer review or safety

oversight, and certainly fails the system of

checks and balances in place to prevent

catastrophes like these.

The NTSB’s stated role is not to lay blame, but

some would say that’s exactly what we do when we

apportion causation. The human failing that

affects all of us is complacency. It is not a

term the NTSB uses often, but in my opinion, it

is present in nearly every accident and crash.

We are creatures of habit, and when we become

comfortable through long repetitive experience,

the guard often comes down – periodically with

disastrous results. This is precisely what

safety management systems are designed to

prevent – to trap errors in process before they

become catastrophes. While disasters may be

perfectly clear in hindsight, the best

organizations take proactive measures –

constantly.

Schedule pressure, economics, overconfidence,

and complacency all work to counter good

intentions and too often create tragedy.

It is my fervent hope that the organizations

involved will take the NTSB recommendations (see

box) seriously and quickly implement them. The

lives lost and the families disrupted deserve at

least that much.

Key recommendations from the NTSB report

The National Transportation Safety Board made

the following key safety recommendations,

primarily to the Florida Department of

Transportation:

-

Require that the independent peer review for

category 2 bridge structures includes

checking and verifying the design

calculations used for all nodal forces

-

Require

the independent peer-reviewed to submit a

prequalification letter showing that it is

qualified in accordance with Florida

Administrative Code

-

Specify

that when structural cracks are initially

detected during bridge construction, the

engineer of record, construction engineering

inspector, design

and build contractor, or local agency that

owns or is responsible for the bridge

construction immediately close the bridge to

construction personnel and close the road

underneath; fully support the entire bridge

weight using construction techniques that do

not require placing workers on or directly

under the bridge during installation; and

restrict all pedestrian, vehicular, and

construction traffic on the bridge until the

complete support is in place and inspected

-

Require

personnel to monitor and inspect all local

agency bridge projects determined by the

department to have uncommon designs

-

Add

a discussion about redundancy to the

Structures Manual, Structures Design

Guidelines, emphasizing uncommon bridge

designs

Additionally it recommended that the American

Association of State Highway and Transportation

Officials and Federal Highway Administration:

And to Figg:

|